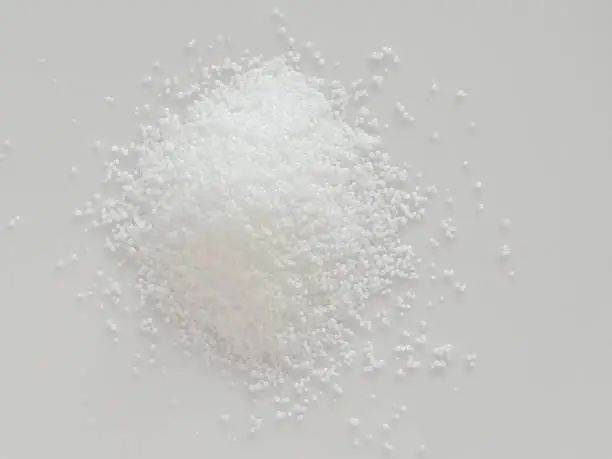

If you’re looking for a rubber grade that’s both high-quality and affordable, then stearic acid 1810 is a great option. This acid is a white, crystalline solid that’s odourless and insoluble in water.

It’s mainly used as a hardening agent, but it can also be used as a lubricant, an antifoaming agent, and an emulsifier. One of the best things about stearic acid 1810 is that it’s compatible with most other rubber grades. It also has a relatively low melting point, which makes it easy to work with. In addition, it’s relatively inexpensive, so you can get a lot of bang for your buck.

Why Stearic Acid 1810?

Stearic acid is one of the most extensively utilised oleochemicals nowadays. The predominant colour of stearic acid is often white while it is a solid and crystalline material. It might have a light order attached to it or not have any scent at all.

The hydrolysis of common animal or vegetable fats and oils produces stearic acid. Unsaturated fatty acids in liquid form are distinguished from saturated fatty acids in solid form using pressing techniques. The chemical grades of stearic acid are then produced by fractionating the crude stearic acid. The various grades are based on how often stearic acid is pressed. There are several industries that make use of stearic acid frequently and Rubber Grade stearic acid is one of the most common grades of stearic acid used in the market.

Get the finest stearic acid on the market from the most reputable and trustworthy stearic acid source in the United States. Sage oil LLC is a reputable name among the top suppliers of rubber-grade stearic acid when it comes to providing various grades of stearic acid for various industries. Sage oil takes the lead as we provide a wide range of commercial grades of stearic acid at competitive prices for your company.

Continue reading to learn how stearic acid 1810 is the Perfect Rubber Grade stearic acid for your business needs.

The Benefits of Stearic Acid 1810:

There are several benefits of using Stearic acid 1810 for your business:

- Hardening material: When stearic acid is combined with softer waxes like paraffin, it hardens as it cools. In the candle-making industry, this property is advantageous.

- Activator: Stearic acid is a common activator used in various chemical reactions because it helps catalyse molecules to start a general reaction. Stearic acid combines with zinc oxide during the procedure, acting as an activator. Stearic acid also acts as a secondary lubricant.

- External lubrication: Stearic acid can also be used as an external lubricant on the surface of a product. Stearic acid is frequently used by businesses to remove successful items from mould by acting as a mould-release agent.

- Internal lubrication: As a fatty acid, stearic acid has both polar and nonpolar components. Stearic acid assists in the reduction of viscosity in concentrations and the improvement of product flow. It aids in the stabilisation of polymers as well.

- Mould release: Stearic acid is also used to get wax out of moulds. When stearic acid is added to the wax, it shrinks in size as it cools. This allows the finished product to be readily removed from the mould. The stearic acid blends nicely with the molten wax, and the candle may be easily removed.

How to Choose for Your Needs?

There are several industries where stearic acid 1810 is used. Some of the common industries are:

Cosmetic industries:

- Cleansers and soaps: different grades of stearic acid, especially 1810 are commonly used during the formulation of soaps and cleansers. It acts as a thickener in soap formulations, helping to solidify the formulae into solids and eliminating the thin and watery sensation of watered-down soaps.

- The surfactant of stearic acid effect reduces oil surface tension, making it simpler for oil and water molecules to mix properly.

- Stearic Acid prevents emulsions from separating into distinct layers of water and oil in this way. This improves the efficacy and shelf life of a product.

- This also implies that finished goods containing Stearic Acid do not need to be shaken as vigorously before use. Stearic Acid acts to remove excess oil, perspiration, and filth from the skin and hair.

- In creams and lotions: When stearic acid is added to lotion compositions, it acts as a thickening agent, adding richness to the finished product’s texture.

Non-cosmetic industries:

Candle-Making industries:

- Candle industries commonly make use of stearic acid on The paraffin wax candles commonly available on the market are fragile since the wax melts quickly. The capacity of stearic acid to serve as a hardener is one of its most essential properties. When stearic acid is combined with paraffin wax, it hardens it. The longer the wax lasts, the harder it becomes. When stearic acid is combined with paraffin wax, it produces a long-lasting candle, according to several studies and techniques.

Why Sage Oil for Stearic Acid 1810

When it comes to bulk supplying stearic acid 1810, Sage Oil LLC is the leading manufacturer and supplier.

We have been offering and supplying the highest quality of rubber-grade, triple-pressed industrial-grade stearic acid for every manufacturing industry.

With Sage Oil’s advanced supply chain technology, getting the best rubber-grade stearic acid is easier than ever. Contact Sage Oil LLC for the most affordable and highest-quality stearic acid available.

Get your quotation now!

Frequently Asked Questions

What is stearic acid?

A waxy, yellow-white material called stearic acid is a kind of natural fatty acid. The majority of the time, it comes from animal fats like tallow and lard or cocoa butter and shea butter.

What is the purpose of stearic acid: rubber grade?

In addition to house cleaners, candles, plastics, lotions and hair care products, it is a frequently used component in these items.

Where can I get the best quality stearic acid for my business?

You can get the best quality stearic acid at Sage Oil LLC. with an assurance of trust and premium quality.